SWISS optio change-over

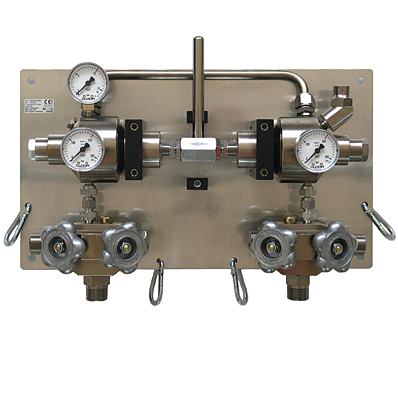

The change-over station at a glance:

- for an uninterrupted gas supply from single cylinders or cylinder racks

- for the connection for up to four single cylinders or two racks of cylinders

- with integrated purging valves

- change-over pressure up to 10 bar (permanently preset)

- as an option, with emergency supply feeding and / or with external alarm

- additional option : with low pressure regulator as second pressure stage and emergency supply feeding completely mounted on panel

The automatic change-over station for medical gases guarantees for an uninterrupted gas supply from two cylinder racks or from two to four single cylinders (1 or 2 cylinders each side).

The change-over station consists of two high-pressure shut-off blocks, two high pressure reductions valves that are connected on the low-pressure side with indication of the respective cylinder pressure and a relief valve. All components are mounted on an aluminium plate.

The high pressure shut-off blocks have two connection options (lateral and from below) and have integrated purging valves. The high pressure connections are fitted with sinter filters and with back-flow valves.

The change-over works on the principle of differential pressure. If the cylinder pressure on one side falls below the set supply pressure, the system will be supplied from the other side through the defined differential pressure. The change-over is switched ready for operation again by operating the change-over lever, and the cylinders on the empty side must be replaced.

The change-over stations are certified according to EN ISO 7291 and EN ISO 10297. The integrated pressure regulators are certified according EN ISO 10524-1 (GM8220), resp. according EN ISO 10542-2 (GM8100). CE marking according to Guideline for Medical Products 93/42/EEC.

Download files

Technical data:

- Classification

equipment class according to CE Guideline 93/42 EEC, Annex IX, class II b

- UMDNS-Code

18-046 (nomenclature for medical products)

- Inlet pressure

200 bar

- Outlet pressure

3 – 10 bar (permanently preset at the factory on request of the customer)

- Flow

GM8220 : 55 Nm3/h / GM 8100 : 80 Nm3/h

- Gas

AIR, O2, CO2, N2O, He, Xe, , mixtures of test gases

- Inlet

3/4“ outer thread, lateral and from below (if the second inlet is not required, it is closed off with a sealing plug)

- Outlet

vertically upwards, G1/4“ inner thread flat seal

- Material

brass nickel plated, stainless steel, EPDM diaphragm

- Sealing material

PEEK, PA6.6, EPM, POM, PU

- Operating temperature

-20° up to + 60ºC

- Dimensions

W x H x D: 36 x 31.5 x 15 mm (GM8220) / 44 x 36 x 15.5 cm (GM8100)

- Weight

10.2 kg (GM8220) / 14.5 kg (GM8100)